Skip to contentWhat’s the difference between the tilting function in x-ray inspection system

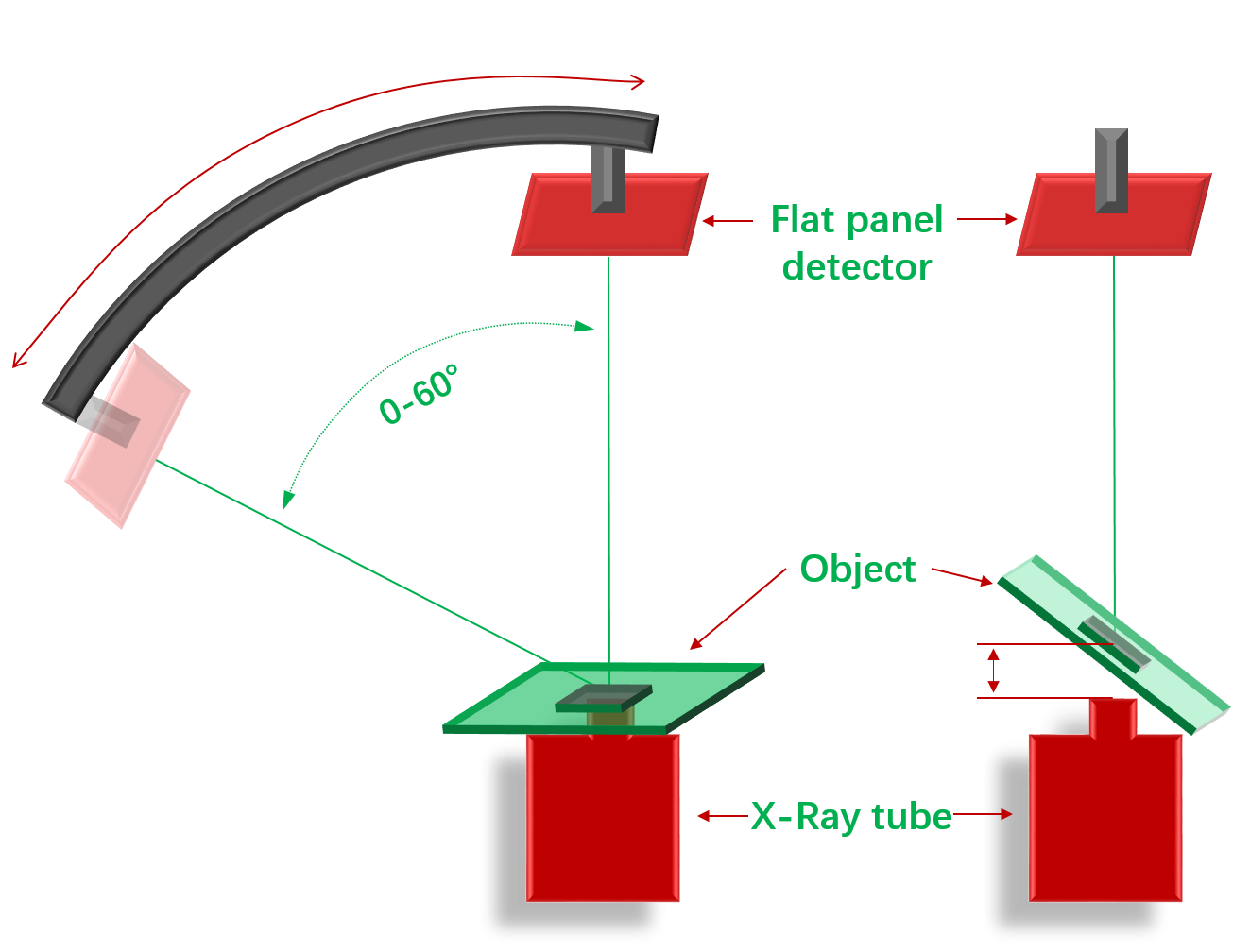

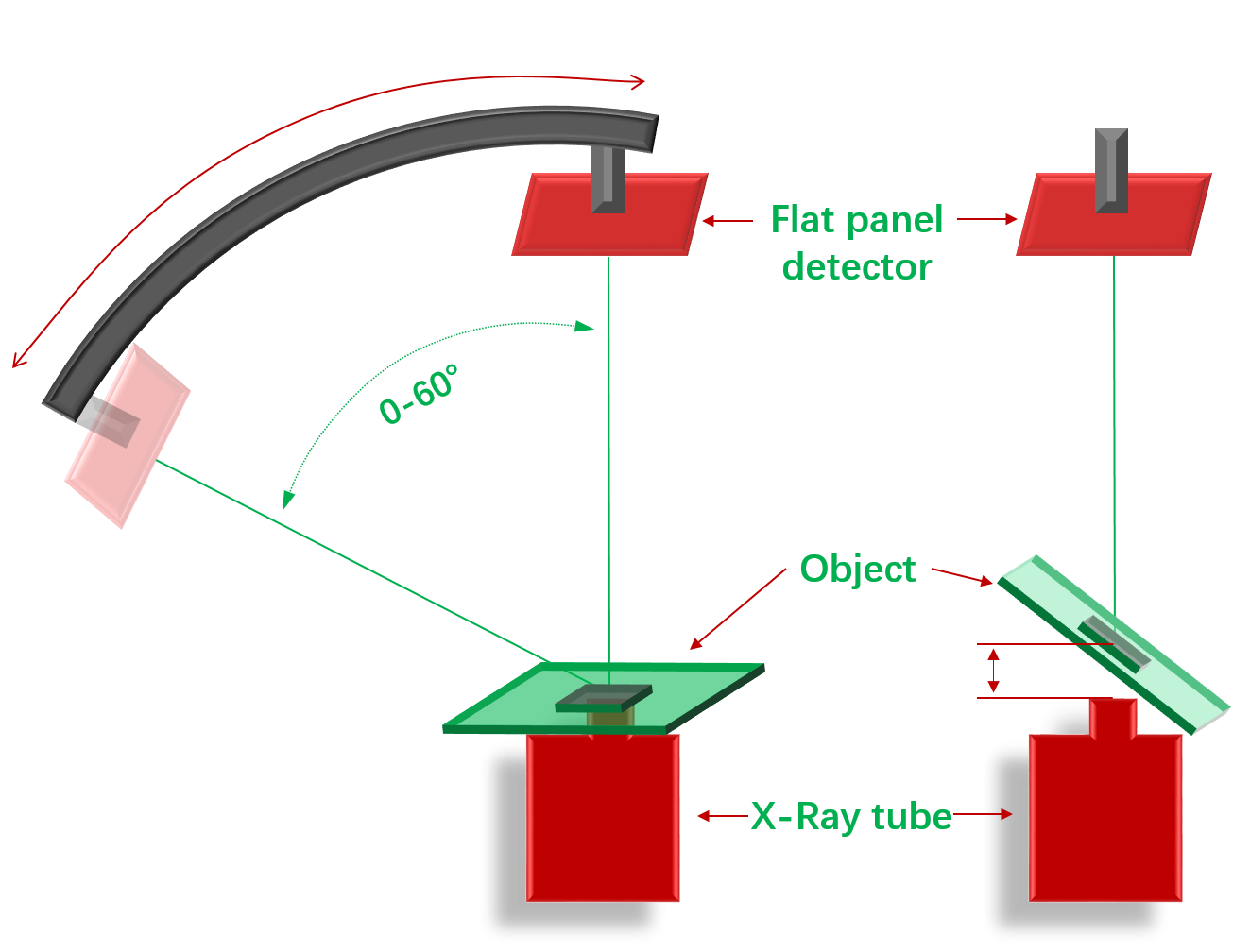

When you want to get a 2.5D x-ray image from wellman’s x-ray inspection machine, you will need to use the tilting function. The X-ray inspection system’s tilt function is usually implemented in two ways. One is the tilt of the flat panel detector. Wellman X-ray inspection system X-6800 uses this method. The other is the tilt of the table. Earlier models launched by some manufacturers use this method because their X-ray inspection system uses heavy image intensifiers to receive X-rays. The figure below is a schematic diagram of the tilt of the flat panel detector and the tilt of the table. The difference between the two is obvious.

So, what are the advantages and disadvantages of each of them?

The tilt of the table:

Advantage:

1. The machine can be smaller. As shown in the figure, the tilt of the table only takes up and down space and does not take up left and right and front and backspace, so there is no need to increase the length and width of the machine.

2. Simple structure, no slide rail required. You only need to add a motor for tilting the table, and it can tilt plus or minus 60°.

3. The device can be equipped with a heavy and cheaper image intensifier, which can avoid the use of high-power motors and thicker slides to tilt the image intensifier.

4. Reduce costs. There is no need for slide rails, and no need to increase the length and width of the device, which means that less metal plate and lead plate, and you can also use image intensifiers that are cheaper, then it can save a lot of costs.

Disadvantages:

1. Lower magnification. In the case of tilt, the table should be farther away from the X-ray tube to avoid hitting the X-ray tube, so the image can only be enlarged to half of the maximum.

2. The poor load capacity of the table. Only the tilting axis instead of the four sides of the table can bear the weight.

3. When the table is tilted, the objects above will fall off, and it must be equipped with a jig. Before tilting, you must use a jig to clamp the object, which affects the efficiency.

The tilt of the flat panel detector:

Advantage:

1. It doesn’t affect the magnification. The X-ray tube and the table can be infinitely approached and can be zoomed in to the maximum when tilted.

2. The four sides of the table can bear loads without reducing the loading capacity of the table.

3. No jig required. Convenient for users and more efficient.

Disadvantages:

1. The machine is bigger. As shown in the figure, the tilt of the flat panel detector requires a lot of space in front, back, left, and right.

2. The structure becomes complicated. Slide rails, chains and motors are required to guide the flat panel detector to tilt.

3. Can only tilt forward 60°.

4. Higher cost. Requires components such as slide rails, and cannot be equipped with image intensifiers that is cheaper. Bigger machine requires more metal plate and lead plate.

In general, the tilt of the flat panel detector pays more costs, ensuring that the machine performance (especially the magnification function) is not affected. It can be said that it is more suitable for X-ray inspection system equipped with flat panel detectors. The tilt of the table is a more reasonable design for image intensifier in the past. It can be seen that the new devices launched by the manufacturers of X-ray inspection system are no longer equipped with image intensifiers, so we can predict that in the future, there will be more and more machines are flat panel detector tilting.