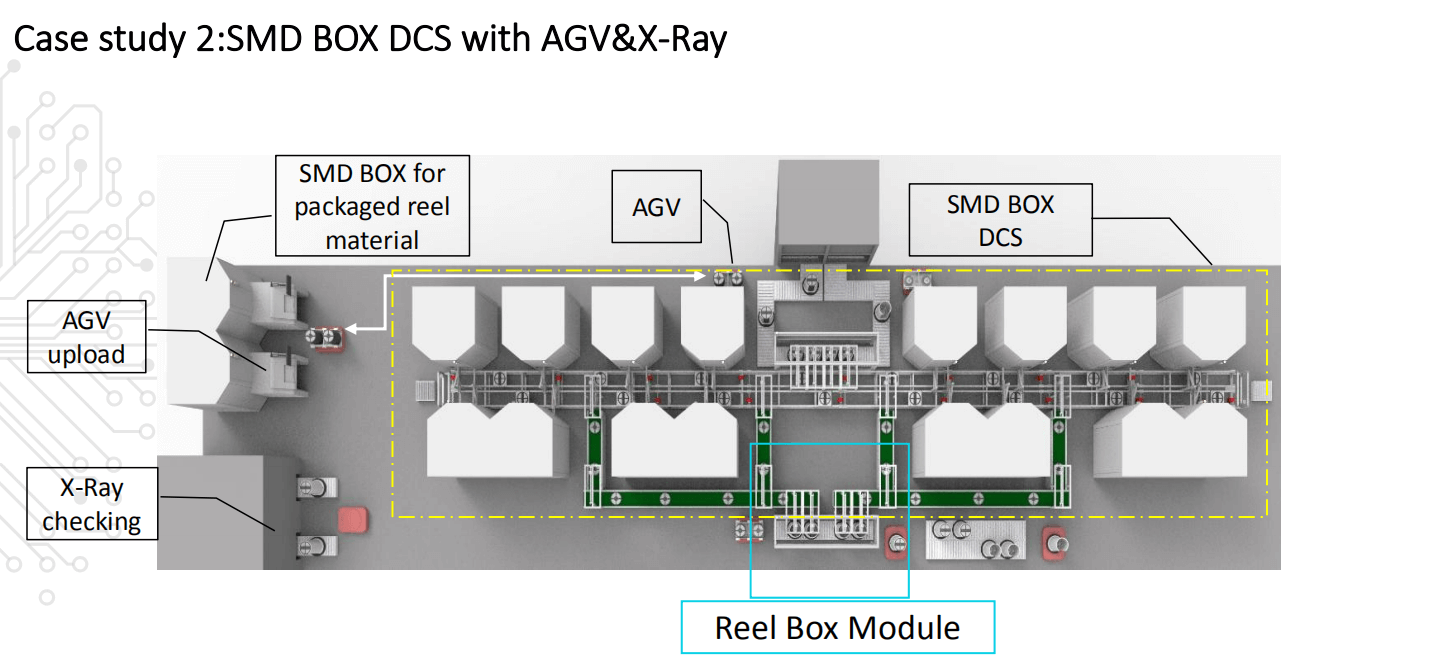

The SMD BOXi is an innovative inline storage system can help to solve the problem of material management in electronics manufacturing, without unnecessary manual movement or AGV. The system is not only a material management equipment but an enhanced unit with cloud management capabilities. By integrating with the SMD equipment, SMD BOXi will save a lot of time on material management! The Inline storage ability enables real-time inventory management capabilities through Work in Progress inventory. And the modular design of the hardware ensures the user to manage materials by adding or adjusting the material amount at any time according to the production capacity.

General Management

By importing the BOM, the user can proceed with the production schedule according to the BOM list. Even without MES, user can also proceed with the production schedule by using the work order from the system. In addition to manage the storage in the SMD BOX, the software is also able to manage the storage out of the SMD BOX according to a virtual warehouse. To solve the problem that storage software is easy to cause the information distortion, our AS/RS robot guarantees the management of automatic storage.

STORAGE@CLOUD:

The cloud computing platform can implement the terminal management of multiple SMD BOXs. Only a simple click on the browser can achieve real-time operation on multiple SMD boxes without installing any client application programs.

• Based on the browser configuration, users do not need to deploy any software

• Front application framework, responsive layout, friendly mobile terminal display

• Bid farewell to production site restrictions, users can access it all through LAN or WAN

• As the core asset of the modern enterprise, data and its security are self-evident. We can help enterprises to use existing IT infrastructure resources to integrate the cloud.

KANBAN

KANBAN, TOYOTA’s production management concept, using – PULL (opposite to PUSH) to optimize plant inventory and provide high efficiency. The utility of the KANBAN enables the user to observe and track the material status distinctly.

MSD Management

The Cloud Storage System is capable of the real-time monitor and improves the temperature and humidity of the storage environment. The software system can display and trace the information according to the MSL level, and improve storage environment based on the preset value

Big Data

• Distributed database structure design

• Massive data storage

• Data storage information based on UID

• Data tracking and analysis

UID System

UID: Unique Identification Number UID Number System is a unique identity in the process of manufacturing electronic materials. The system can not only help users to generate or print bar code but also help users to trace and save the large amounts of data through a distributed database system.

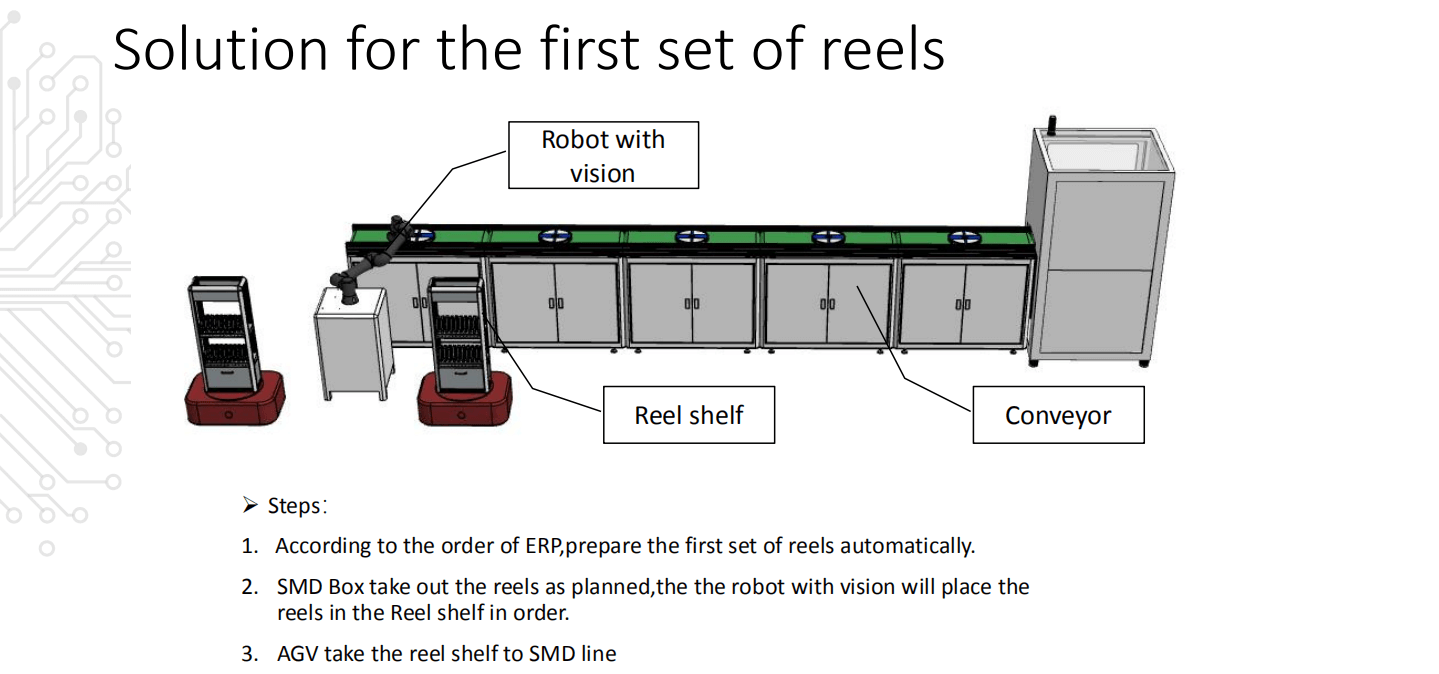

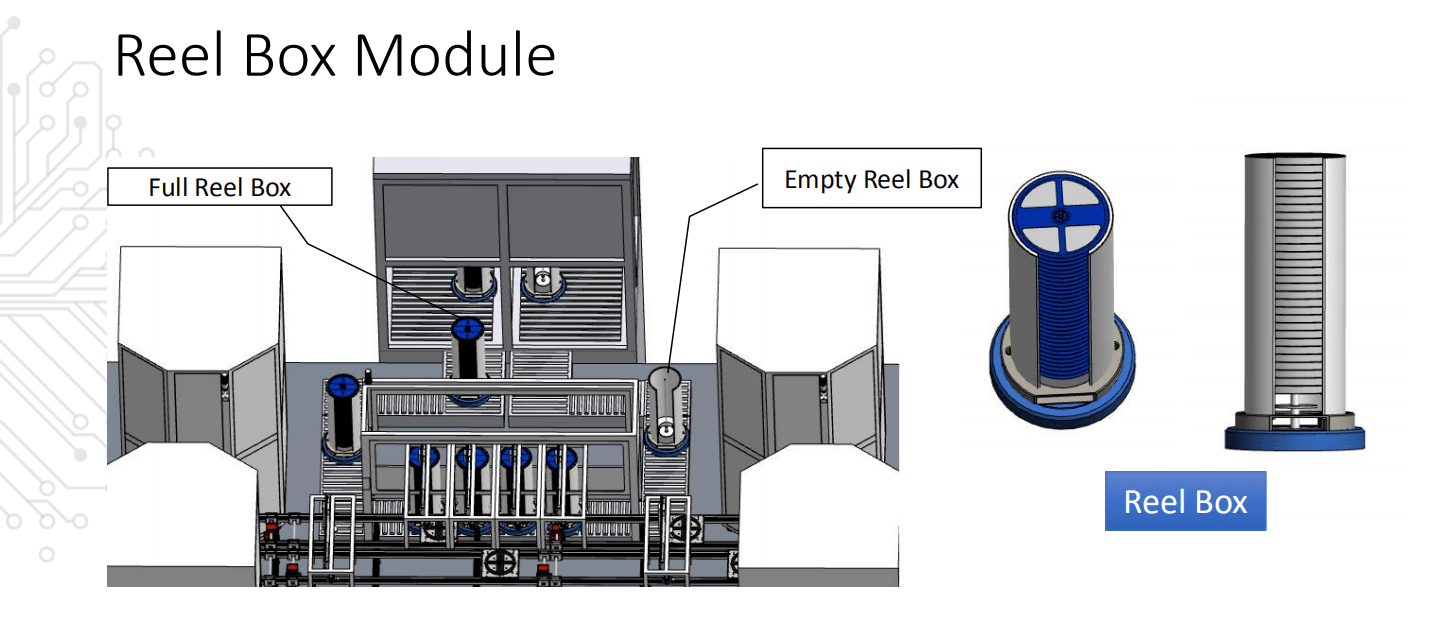

Automated storage and retrieval

Our patented design integrates the material storage system into the production line. By real-time reading of the production process information, the neotype AS/RS robot system can pick up the materials accordingly and timely.

Inventory Strategy

Different types of work orders and components require different retrieval management strategies: FIFO, FEFO, the definition of specific conditions, etc.

M2M

The compatibility with the mainstream pick &place machine help to transmits data like station information and underfeeding information from the pick and place machine.

Real Time Inventory

Material information stored in the cloud (private/public cloud) server can help the user know well of the real-time inventory information. It’s time to say Goodbye to inaction stock!

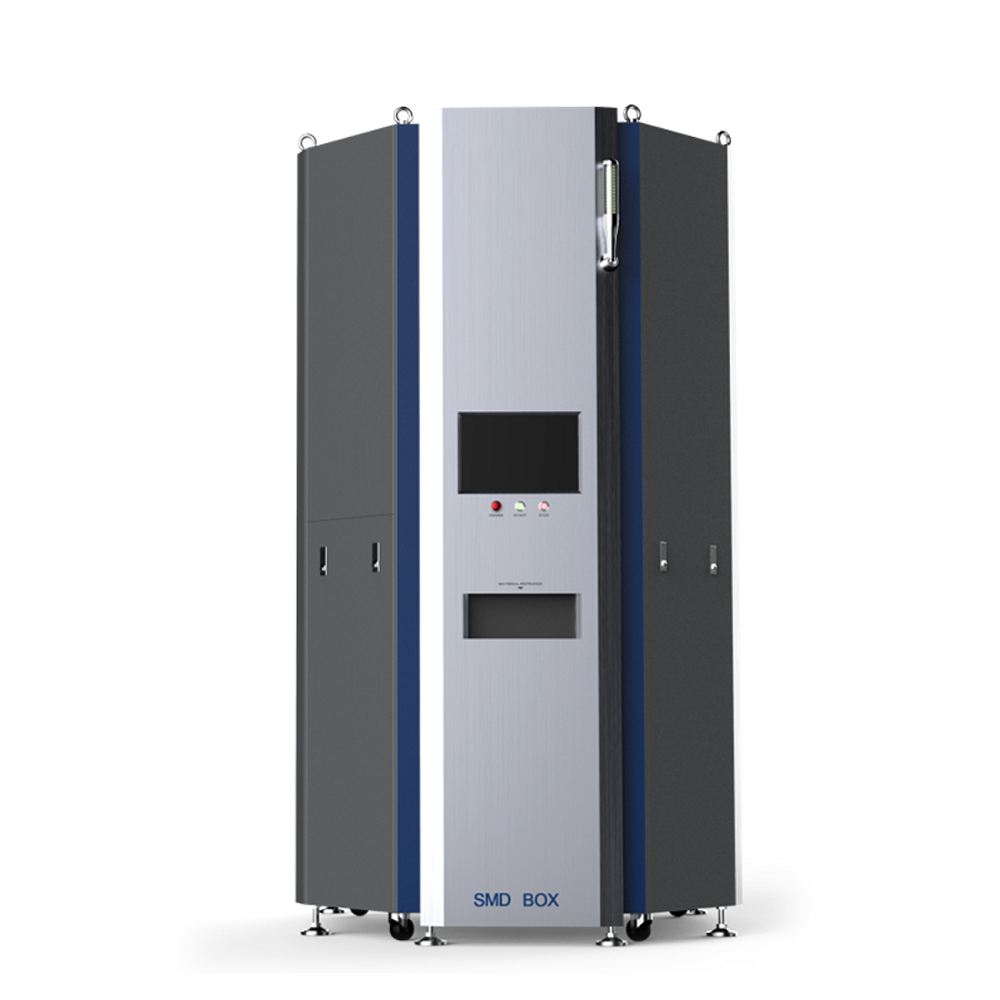

SMD BOXi Features:

- 7” 13” 15” Reel components compatabile

- 2D barcode and matrix support

- Servo motor equiped

- Industry PC controller

- TCP/IP enabled

- Modular design

- ESD material protected

- Capacity:Up to 1000 7” @8mm reels

- MSL control

- Customization capable

- Low maintenance requirements

| Model | SMD BOXi |

|---|---|

| Equipment type | On-Line |

| Client operating system | Windows / Linux / Mac |

| Mobile end support | Yes |

| Software access method | Browser |

| Private Cloud | Yes |

| Server operating system | LINUX / WINDOWS |

| LAN Access | Yes |

| Barcode support | 1D / 2D |

| Material Types | Reels/Waffle plate/LED/The tubular material |

| Storage mode | automatic |

| Trays size | |

| 15 "Material | Optional |

| 13 "Material | Standard |

| 8 "Material | Standard |

| * Large height | 72mm |

| * Small height | 8mm |

| Weight | Great weight of 4 kg * |

| Expansibility | Multi-module can work online |

| MSL Management | Yes |

| Humidity log | Standard |

| Temperature logs | Standard |

| *High capacity | 400 |

| Access time | 6 seconds |

| Air drying system | Optional |

| Nitrogen generator | Optional |

| Mounter Communications | Optional |

| MES Communications | Optional |

| Dimensions | 1100x1100x2100 mm |

| Weight | 350kg |

| Power supply | 220v |

| Power | 4KW |

| Electric current | 10A |

| Working environment | 15 - 30 ° C |

| Environmental requirements | 10--60% |

| Noise level | 50dB |

| Compressed gas | 6-10bar |